We've always been fascinated by modular home builders. We wanted to know how they turn raw materials into homes in a factory. It's a journey of discovery.

Prefabrication is changing Australian housing. It's fast and precise. Imagine seeing your home come together in a factory, with the latest tech and skills.

Exploring the prefabrication process shows a new world. It's different from old construction ways. Modular builders use new tech and methods to make homes better.

The journey of prefabricated housing in Australia is truly inspiring. It shows how innovation and adaptation have changed the game. Modular home makers have made a big impact on our homes.

After World War II, prefabricated houses became a key solution to Australia's housing crisis. These homes were affordable, practical, and built fast. They helped soldiers and families quickly find a place to live.

The prices of prefabricated houses were much lower than traditional homes. This made owning a home possible for more people. Important changes included:

Today, prefab technology has come a long way. Advanced computational design, precise engineering, and eco-friendly materials have changed the industry.

Now, prefabricated houses prices show the advanced tech used. The market is growing fast. Modular home makers are using the latest tech to offer:

Our prefab housing sector is at a thrilling point. It's where tech, sustainability, and affordability meet.

Modern modular home builders are changing the game with new tech. The way they build homes has changed a lot. They use advanced digital tools for better precision, efficiency, and customisation.

At the core of this change are new systems that change how we build:

Our builders use state-of-the-art computational technologies to cut down on mistakes. Robots can cut, shape, and put together parts with amazing accuracy. This ensures homes meet Australia's strict building standards.

Some big tech steps forward in building include:

These advances make building faster, waste less, and is more eco-friendly. Modular home builders are leading the way in Australian home building with these new technologies.

Quality control is key in making modular homes. It sets professional makers apart from others. We aim for the best in safety, durability, and performance in every home.

The quality check starts before anything is built. Modular home makers test each part to high standards.

Our quality control has many important steps:

We don't just meet the rules. Mobile home builders must follow Australian standards. But our makers do more with better engineering and precision.

Keeping records is a big part of our quality control. Every step of making is written down. This makes sure everything is clear and accountable.

Our method means homes are top-notch when they arrive. They're reliable, efficient, and meet the highest standards.

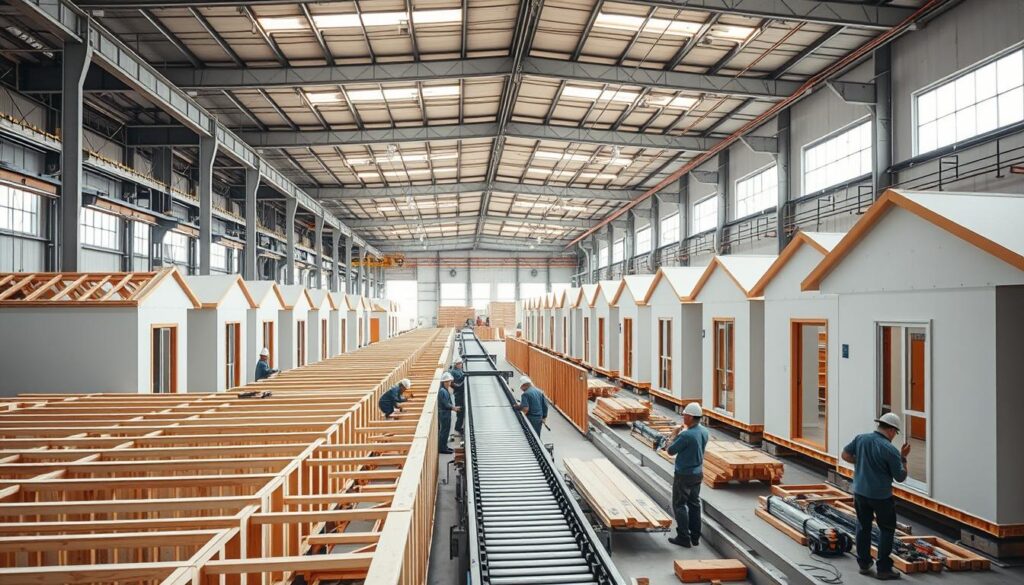

Step into the world of modular home builders in Australia. Here, innovation meets precision engineering. Our virtual factory tour shows how raw materials become stunning, high-quality homes.

Modern modular home builders have changed construction with advanced facilities. These factories are the top of Australian manufacturing tech. Skilled workers carefully make each home module with great detail.

The prefabrication process starts with quality-checked materials. Modular home builders use the latest tech to make homes that meet Australian standards. These homes are both standard and customizable.

| Factory Feature | Key Benefit |

|---|---|

| Precision Manufacturing | Minimal waste and maximum efficiency |

| Quality Control Systems | Consistent high-standard production |

| Skilled Workforce | Expert craftsmanship and technical expertise |

Our tour shows that today's modular home builders do more than build houses. They create complete living solutions. These homes are the future of Australian homes.

The prefabrication process is a game-changer in home building. It changes how modular home makers create top-notch homes. We'll look at the detailed steps that make homes come to life.

Modern prefabrication uses advanced engineering and manufacturing. Modular home makers have a fast and efficient way to build homes. This ensures quality and saves time.

The first step is careful design and engineering. Our experts use the latest software to make detailed digital plans. These plans are the base for each modular home.

In our top-notch facilities, we make each home part with great care. The prefabrication method ensures quality and consistency. It's better than traditional building.

Before leaving, each home gets a thorough check. We make sure every module is safe and works well.

Precision packaging keeps each module safe during transport. This means the home arrives in perfect shape.

Modular home builders are changing the game with their green approach. They're making building homes more eco-friendly. This is changing how Australians see home building.

There are many benefits to prefabricated houses. These benefits go beyond just the cost. They include long-term environmental gains:

Factory-controlled environments help builders use materials better. Our method cuts waste by up to 80% compared to traditional homes.

Energy efficiency is a big plus. Prefabricated houses use the latest green tech. They're ready for solar panels and have top-notch insulation. These homes are the future of living green.

"Sustainable building isn't just a trend—it's our responsibility to future generations."

Choosing modular homes means less harm to the environment. It can also save money in the long run. This is because these homes use less energy.

Understanding the costs of building a home can be tough. We're looking into how prefabricated houses compare to traditional building. This will help you see the real value of modular homes.

Prefabricated houses often save a lot on materials. Modular builders buy in bulk and cut down on waste. Here are some key savings:

Modular homes are built in a controlled factory setting. This leads to big labour savings. Traditional sites face weather delays and other issues. Prefabricated homes offer:

Prefabricated homes also save money over time. They are energy efficient and built to last. This means less maintenance and lower bills. Our studies show savings of up to 30% over time.

The future of home construction is smarter, more efficient, and increasingly modular.

Modular home builders now offer more than basic designs. Today, prefabricated homes come with a wide range of custom options. This is thanks to modern modular home builders who have changed the game in personalized housing.

Homeowners can now get a home that's truly their own. They use advanced design tools that change how homes are built. These tools include virtual design platforms that let customers:

Customization goes beyond just looks. Modular home builders know every family is different. They offer many ways to personalize a home:

| Customisation Category | Available Options |

|---|---|

| Architectural Styles | Modern, Classic, Coastal, Rural |

| Interior Layouts | Open Plan, Traditional, Multi-Generational |

| Sustainable Features | Solar Panels, Water Harvesting, Energy-Efficient Designs |

Technological innovation has truly transformed the modular home building landscape. What was once seen as a limitation is now a big plus. Mobile home builders now offer more personalization than ever. Homeowners can make spaces that show off their style, lifestyle, and needs.

The journey of a modular home doesn't end when it leaves the factory. Modular home manufacturers put a lot of effort into making sure each part arrives safely and on time. We'll look at the detailed logistics of getting these homes to their final place.

Getting prefabricated modules to their destination needs careful planning and the right equipment. Every module is prepared with precision for its journey.

When modules get to the site, our skilled teams make sure everything goes smoothly. The installation process includes:

"Modular construction reduces on-site build time by up to 50% compared to traditional building methods." - Australian Construction Innovation Council

Our modular home makers know speed and accuracy are key. The whole assembly can be done in days. This cuts down construction time and reduces disruption to the area.

Prefabricated homes have faced many false beliefs. These don't match today's building methods. Our mobile home builders have changed the game, making high-quality homes that prove these myths wrong.

Let's look at some common myths about prefabricated houses prices and building:

Today's prefabricated homes are built with advanced techniques. They often beat traditional houses in quality. Strict checks ensure top standards.

Modern modular design lets you choose from many styles. You can pick materials and finishes to make your home unique.

Modern prefab homes use strong materials and smart designs. They can handle tough Australian weather better than many traditional homes.

Our studies show prefabricated houses can be cheaper than building from scratch. Mobile home builders use new tech. This cuts down on waste, saves on labor, and speeds up building.

Modern prefabrication isn't about compromise—it's about smart, efficient housing solutions.

Knowing these truths helps homeowners choose wisely. They can find modern prefabricated homes that offer great value, quality, and design freedom.

Modular home prefabrication is changing how we build houses. Modular builders in Australia are using new tech and methods. This makes homes better and faster to build.

This new way of building homes has big benefits. It means homes are built with more care and less waste. Homeowners save money and get homes that are smart and green.

The future of modular homes looks bright. New tech will bring even more choices in design and sustainability. Homes will be faster to build and better for the planet.

Looking back, it's clear that prefabricated homes are here to stay. They offer a smart, green way to build homes. They fit perfectly with the Australian way of life.